Würth Additive Group, a Würth Industry North America company and a provider of physical and digital inventory, announced that it has signed an agreement with Kurtz Ersa Inc. Kurtz offers technology in the fields of electronics production equipment, molding machines, and automation.

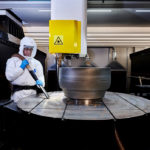

Würth will support higher-end production through Kurtz Ersa’s proprietary Perfect Angle Printing technology, creating optimal properties for metal processing.

The agreement expands Würth Additive Group’s suite of 3D printing technology offerings by introducing the Alpha 140, which combines innovative additive-manufacturing technology with simple operation at low-system costs.

“Kurtz Ersa has been creating well-built and sustainable products for over 200 years,” said AJ Strandquist, CEO of Würth Additive Group. “The innovations they have brought to the market since 1779 are remarkable, from their initial business of a water-driven hammer to soldering, to molding equipment — they truly understand the needs of a manufacturing environment, and we are excited to present this innovation and technology to our customers.”

The agreement broadens Würth Additive Group’s ability to support high-end production through Kurtz Ersa’s proprietary Perfect Angle Printing technology.

The Alpha 140’s fiber-coupled diode laser is guided coaxially to the powder bed, enabling a constant focus diameter across the entire build space and creating optimal properties for metal processing. Through innovative re-engineering, they have removed up to 40% of the machine’s cost and a historical point of failure seen on other systems making it a true plug ‘n produce machine.

“Kurtz Ersa and Würth have had a long and productive history as customer and supplier,” said Dan Hill, CEO for Würth Industry North America. “By reimagining status quo inventory management, we can drive down costs, not by cutting corners but instead by intelligent engineering. We’re happy to support our customers through more efficient and profitable inventory solutions.”

Tell Us What You Think!