Würth Industry North America (WINA), an industrial distributor of supply chain solutions for fasteners, MRO, and safety equipment, announced that it formed a new company: Würth Additive Group.

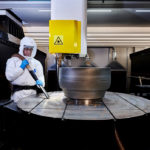

Würth Additive Group will provide customers with end-to-end industrial 3D printing products and services.

Incorporated in Delaware, the Würth Additive Group to provide expanded 3D printing products and services, including financing, as well as rental options on equipment.

“We are thrilled to bring innovative digital supply-chain solutions to our customers,” said Dan Hill, chief executive officer for Würth Industry North America. “By integrating industrial 3D printing technology with our existing inventory programs, we can offer faster time to market, lower inventory costs, and improved environmental sustainability practices. We’re able to cut out the sourcing, purchasing, and transportation costs and deliver the value directly to the customer.”

WINA began providing additive solutions to customers in late 2017, with rapid prototyping and printing production tools. It now offers full digital Kanban solutions by integrating 3D printing technology in its existing vendor-managed inventory programs.

“We’re excited to offer rental and financing options and provide additive manufacturing solutions to a wider market,” said AJ Strandquist, newly appointed CEO of Würth Additive Group. “Our mission is to enable, implement, and support a digital supply chain solution that is dependable and beneficial for our customers to operate. We do this by offering a clear implementation process, cost-saving options, on-going support, a strategic supplier portfolio, and financial services for instant return on investment.”

WINA signed a global distribution agreement with Markforged, a provider of industrial metal and carbon fiber 3D printers, in March of 2020, after working with the company to provide 3D printing solutions to Würth customers since 2019.

WINA has also added several strategic suppliers to its portfolio of additive solutions, offering a wide range of printers and materials for industrial applications. Its digital supply chain strategy includes additive manufacturing/3D printing, digital part files, and inventory assessment software that help customers leverage existing technology and find significant cost savings while reducing operational risk.

Tell Us What You Think!