Written by Dr. Jody Muelaner

Gaskets are used in many applications, including to create a high-pressure seal between pipe flanges in industrial pipe work.

A gasket is a flexible spacer that sits between two mating components. Gaskets are typically used to create a seal. They are made of a more flexible material that the components, allowing the gasket to fill any gaps due to surface imperfections. Gaskets may also be used to prevent vibration between components.

The mating surfaces are often nominally planar and a gasket is cut from sheet material to fill the gaps between them. Materials used for gaskets include rubber, polymers, metal, fiberglass, paper and felt. Components are typically bolted together, exerting considerable pressure on the gasket. An O-ring is also a type of gasket.

It’s extremely important that gaskets are correctly specified for their intended operating conditions. Some important considerations are the pressure, temperature, any hygiene requirements and the presence of any corrosive substances.

The primary purpose of most gaskets is as a seal, preventing ingress or escape of fluids. However, many gaskets also function as a safety pressure release. For example, it may be a vital function of a pipe gasket that if pressure builds up the gasket will fail before the pipe bursts.

Another consideration is whether a gasket must be reusable. Many gaskets allow parts to be disassembled and then put back together, with the original gasket forming a seal once again. Some gaskets, however, can only be tightened to form a seal once and must be replaced if the components are taken apart.

Some common types of gasket include:

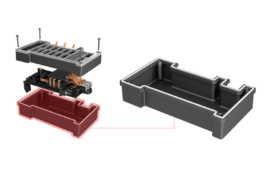

- Gaskets cut from sheet material to seal engine and gearbox housings, for example the head gasket in an engine.

- Gaskets cut from neoprene rubber to create a weatherproof seal, for example in electrical enclosures .

- Pipe gaskets which resemble a large washer and sit between pipe flanges.

- O-rings, a torus shaped loop of elastomer which can be seated in a groove and compressed to form a seal.

Tell Us What You Think!