The revolutions in electrification and autonomy are creating an exponentially growing demand for highly reliable automotive electronic components — and a need to optimize every aspect of component design and manufacture. Answering this challenge, Henkel has developed an innovative solution for silicone liquid gasketing for the next generation of automotive electronic components.

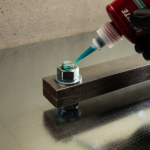

Henkel´s new 1k RTV silicone form-in-place-gasket (FIPG) solution dispense, assemble, and test in-line reduces staging times and creates an immediate seal on assembly.

Loctite SI 5972FC is a one-part RTV silicone form-in-place-gasket (FIPG) solution that accelerates the process of electronic module sealing.

With adhesion to a range of metal and plastic surfaces, the highly dispensable liquid silicone material has been specifically designed to pass OEM’s leak or blow-out pressure tests immediately after assembly — minimizing the need for time and space-intensive staging.

With its tin-free catalyst system, Loctite SI 5972FC also provides a REACH-compliant solution for safer, more sustainable manufacturing.

Module sealing is an essential final stage in the assembly process. While liquid silicone gasketing solutions have proved a versatile option that can address multiple configurations without the inventory challenges and manual assembly required by traditional rubber O-rings, the room temperature vulcanization (RTV) curing process can be time consuming.

To meet stringent OEM pressure testing, post assembly staging to achieve a full cure can take several days. This not only prolongs cycle times but also consumes precious floor space in the manufacturing environment.

Loctite SI 5972FC changes all this: Thanks to its unique design, it can pass a 3-psi leak test immediately after assembly. Even higher leak test pressures can also be passed in relatively short periods. In addition, the material’s non-corrosive outgassing and low volatility (D4-D10 <0.1%) makes it ideal for sensitive electronic components.

Recommended applications include Electronic Control Units (ECU), Bussed Electric Centers (BEC), Battery Disconnect Units (BDU), Electrical Power Steering (EPS) Power Packs, and ADAS (Radar) components.

Loctite SI 5972FC is a further breakthrough product in Henkel’s range of gasketing solutions tailored to automotive applications.

Safer, more sustainable components

Through its tin-free catalyst and alkoxy curing system, this one-component dispensable silicone material provides a REACH compliant approach to sealing electronics. By avoiding the need for curing ovens, Loctite SI 5972FC also helps manufacturers reduce energy usage and carbon emissions.

As a champion of sustainability, and a forward-thinking, valued partner to the automotive industry, Henkel is innovating new materials, processes and solutions to help deliver greener and safer solutions.

In addition to developing tailored solutions to meet the merging challenges of EV manufacturing, Henkel aims to support its customers and partner along the entire automotive value chain to reduce the carbon footprint and environmental impact of every aspect of vehicle manufacture. This includes reduced waste, water and energy usage during manufacture and lower supply chain emissions.

“Today, it is vital to fully understand the impact of materials used in a component — whether this relates to the impact on manufacturing efficiency or the risks to human or environmental safety. Loctite SI 5972FC has been created to help manufacturers address this spectrum of challenges,” explains Arthur C. Ackerman, business development manager, Automotive Electronics at Henkel.

Tell Us What You Think!