There’s no difference other than the terms. Lag screws are lag bolts and vice versa — the terms are used interchangeably and refer to extremely tough fasteners that can withstand heavy loads. These large wood screws/bolts don hexagonal heads and typically fasten heavy lumber or other materials with intense loads.

It’s understandable how both terms (lag “bolt” vs. “screw”) became synonymous with these fasteners, as they exhibit the characteristics of a bolt and a screw. Bolts are usually assembled with a nut and have machine threading. Screws are fastened by turning its head while their threads cut into the material. Lag screws/bolts do both.

But it’s important to point out that while adding a nut for extra strength and security is possible, this is not always essential for assembly. The ideal choice will depend on the applications. Unlike bolts, which require a nut to secure them in place, lag screws are self-tapping fasteners designed to be threaded directly into the material.

Technically, lags should be referred to as screws and not bolts. But what’s most important is that they’re relatively easy to install, provide a strong and durable connection, and are reliable for use in heavy-duty material.

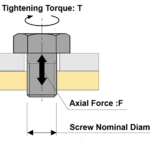

To install lag screws, pre-drill a hole slightly smaller than the diameter of the screw’s threads to make it easier to drive it into the material. This helps prevent splitting and ensures a secure fit. These fasteners have a threaded shaft that cuts into the wood or other material as it’s tightened. The other end typically has a hexagonal head, which can be turned using a wrench or a socket.

What makes lag fasteners unique?

Aside from offering some of the characteristics of bolts and screws, lag fasteners differ from standard wood, self-drilling, or sheet metal screws in size, strength, and threading. Lag screws support much heavier loads than the average sheet metal or wood fasteners and resist pulling out or loosening over time.

Lag screws also require a pre-drilled hole and are at least one inch long and 1/4 inch thick. These fasteners typically feature hexagonal heads without slots on the top surface for a screwdriver. A torque or impact wrench is required for proper fastening.

Typical applications include fastening decks, beams, framing, and most heavy-duty wood construction or structures.

The advantages to using lag screws/bolts include:

- Strength: offer extremely reliable fastening, thanks to their thick shafts and coarse threads — similar to most bolts. This makes them easy to install in heavy-duty applications.

- Size: available in various sizes, from several inches to several feet in length. These fasteners are ideal for use in construction and structural applications.

- Load-bearing capacity: can withstand significant stress without damage, making them ideal for reliable fastening of intense loads.

- Secure connection: depending on the assembly, they can use a washer or nut for added strength and security if necessary. Be sure to double-check the requirements of your project.

- Corrosion-resistance: often made of steel and coated with materials like zinc or galvanized to protect against rust and enhance corrosion resistance.

No matter what you like to call them, lag screws or lag bolts, these fasteners offer strength and durability. When using lag screws, follow proper installation techniques, including pre-drilling pilot holes to prevent wood splitting and ensuring that the screws are driven straight and tight.

Ideally, consult a fastener expert for your project to ensure the correct size and type and a safe and secure connection.

Tell Us What You Think!