As an electrically insulative material, Master Bond’s new EP41S-5Med epoxy is ideal for medical electronic applications.

Master Bond‘s new EP41S-5Med is a two-part epoxy system that meets the requirements of ISO 10993-5 for non-cytotoxicity and can be used for bonding, sealing, and coating in medical devices.

It features high-temperature resistance and excellent strength properties. As an electrically insulative material, it can be used in medical electronic applications.

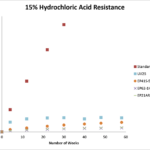

This epoxy was tested against many sterilization methods, such as autoclaving, STERRAD, Cidex, and Steris — successfully resisting a hundred cycles. It’s also capable of withstanding exposure to gamma radiation, ethylene oxide, as well as other aggressive sterilants and chemicals.

EP41S-5Med provides a tensile strength of 10,000 to 12,000 psi and adheres well to a variety of similar and dissimilar substrates, including metals, plastics, rubbers, ceramics, and composites. This compound has a glass transition temperature of 140° to 145° C and is serviceable from -80° to +450° F [-62° to +232° C].

EP41S-5Med features reliable electrical insulation characteristics with a dielectric constant of 3.5 at 60 Hz and a volume resistivity greater than 1014 ohm-cm. The system is black in color and contains no solvents or diluents.

EP41S-5Med offers convenient handling with a 100 to 25 mix ratio by weight. The mixed epoxy has good flow properties with a moderate viscosity of 25,000-30,000 cps. Upon cure, it offers low shrinkage and a hardness of 85-95 Shore D. The new epoxy is available in standard sized units of 1/2-pint, pint, quart, and gallon kits. It’s also compatible with automated gun dispensing systems.

Tell Us What You Think!