Several businesses are gradually reopening and returning to their offices following the threat and fight against COVID-19. For Brighton-Best International (BBI), an essential global supplier of fasteners, tools, and personal protective equipment (PPE), their facilities never closed down. The company had too many customers that distribute to critical industries to even consider shutting down.

Several businesses are gradually reopening and returning to their offices following the threat and fight against COVID-19. For Brighton-Best International (BBI), an essential global supplier of fasteners, tools, and personal protective equipment (PPE), their facilities never closed down. The company had too many customers that distribute to critical industries to even consider shutting down.

However, BBI did put many safeguards in place to ensure employee and customer safety. Here, Steve Andrasik, VP of sales with BBI, answers some of our questions about how the company has managed the pandemic and what changes they’ve made as a result.

Fastener Engineering (FE): Can you first please share a little about Brighton-Best and how the company got its start?

Steve Andrasik (SA): Sure! BBI has been around since 1925 and, for the most part, we’ve served as an industrial fastener company that specializes in socket head-cap screws. However, about 12 years ago, we were purchased by Ta-Chen International or TCI and became a full-line fastener distributor. Since then, we’ve experienced tremendous growth.

As a result of our growth and diversity, we were able to buy our biggest fastener competitor, Porteous Fastener Company (PFC), some five or six years ago. PFC had a couple of divisions aside from just fasteners, including one called Proferred that sold components such as drywall screws and self-drill screws. We’ve since expanded that into a full line of hand tools and a lot more. And, more recently, we acquired Ironclad Performance Wear, a distributor of high-performance gloves.

FE: BBI is still operating as an essential service is that correct?

SA: Yes, we’ve been deemed an essential service. In total, we have 32 warehouses globally, which includes 23 in North America — and we’ve been able to keep them all open. This was very important to our customers. Many actually called or emailed us in early March when the threat of this pandemic first hit, asking us to stay open. Our distributors have government contracts and provide to critical industries that require fasteners. So, it was an easy decision for us to keep the business running, with the proper precautions in place.

FE: What countries are you all located in?

SA: We’re in the UK, Australia, Brazil, Canada, and in 20 locations in the United States.

FE: What types of modifications have you had to make in your facilities to cope with the restrictions that are in place due to COVID-19?

SA: We tried to get ahead of it really early on, which meant sending about half of our inside sales groups home to work remotely. This turned out to be a very good idea and helped us with social distancing in the offices. We were able to space out the cubicles and easily have people work at least six feet away from each other.

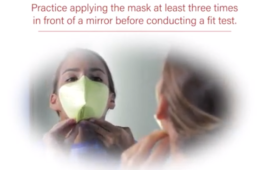

We also put several other initiatives into place. For example, we’ve been checking the temperature of everyone and logging it daily so we can monitor any ranges. So, if somebody spikes one day, we really didn’t want to overreact to that but also had to take it seriously. Tracking these patterns has helped. We also have all employees wearing masks and Nitrile gloves, particularly in the warehouses and we routinely wipe down surfaces in the facilities every two hours. Plus, we do a deep clean of our regional facilities every week.

Additionally, we’ve separated our office from the warehouse. This is to ensure there’s no traffic in between or people going back and forth…just as an extra precaution. All of the measures we’ve been using have been helpful and seem to be working quite well.

FE: Have you had any major challenges or downturns in product demand at this time?

SA: Certainly, some of our customers and the demands are down. But in every market, there are a handful of companies that are extremely busy and doing really well. Obviously, there’s the medical device industry but also home healthcare, such as exercise equipment, and others no one expected.

We offer such diversified lines that we’re able to continue to support safety and personal protective equipment sectors, such as for wipes and masks and such. So, there have been opportunities inside product lines that may not have been there in the past.

We’ve also had a lot of orders for stainless steel products that would make sense given the need for more hospital beds, gurneys, medical trays, or related supplies or what have you. We’re not always made aware of where our products end up but I know many have gone to the medical sector.

FE: How has the communication been with so many people working remotely? Did you have to install any new systems or servers to address security or other concerns?

SA: Yes, actually security was an issue we were concerned about at first. It’s one of the reasons we were leery about letting staff working from home long before this pandemic. But BBI reacted very quickly to COVID, and got the proper equipment and systems in place so we’ve managed better than expected. I’m quite proud and impressed by how quickly they were able to react to and manage our teams.

Have you been able to maintain productivity and positivity during the last few months?

SA: We absolutely have in terms of products going out and meeting customer demands. Although I admit it’s been a challenge on some levels. You know…it used to be that you’d simply walk over to somebody’s desk to ask a question or check on something and now you’re calling them at home or sending them emails or those kinds of things. And, of course, we have weekly meetings and we’re doing a lot of Zoom calls.

Honestly, I didn’t even know what Zoom was before this. But it’s been interesting seeing people work out of their homes — it gives you a different perspective when their dog runs by or you hear their child in the background. In some ways, it’s great to see another almost more personable and human side to people.

Since our outside sales team has been grounded for the past 10 weeks or so, it’s extremely important for us to stay in front of customers and remain connected. Communication is different and I’ll be glad when we can return to the office. I do believe we’ll be going back in June but, gradually, and with very limited staff at first to monitor and ensure safety.

FE: Any final thoughts you’d like to share?

SA: I’d love to believe that we’ve done everything right here, and I have been impressed by the responsiveness of BBI, but it’s been a learning experience as we go. Our employees have all been willing to do whatever is required in this situation and I’m quite proud of everyone. We’ve managed to step up, stay safe, and good communication has been a cornerstone of that. I think we’ll be in a good spot and continue to succeed as we move forward.

Great article. Steve is a pro!

Nice job Steve. We have always been very happy with Brighton’s service and professionalism and feel that the service and stock situation have been seamless throughout this current situation.