Controls inside industrial cabinets now stay cool efficiently thanks to a combination of a conventional air conditioner and a new take on evaporative cooling.

Leland Teschler

Executive Editor

When industrial controls enclosures and server racks get hot enough to demand their own cooling means, the usual approach is to give the enclosure its own air conditioner. Because there is an increasing emphasis on minimizing energy consumption, enclosure makers strive to make enclosure air conditioners superefficient.

That was the motivation for an air conditioner for enclosure cabinets called the Blue e+ created by Rittal GmbH. In the interest of energy efficiency, Blue e+ a/c units combine two different principles to cool enclosure air. The first uses a conventional refrigeration cycle and typical condensing and evaporator coils, an expansion valve, a compressor and a fan. The second method is a kind of evaporative cooling but applied in a novel way.

Evaporate cooling methods have been applied in air conditioning schemes since the 1700s. The most well-known method of evaporative cooling is to draw hot air through a wet pad. Heat from the air is absorbed and used as the latent heat necessary to evaporate water. This evaporation cools the incoming air.

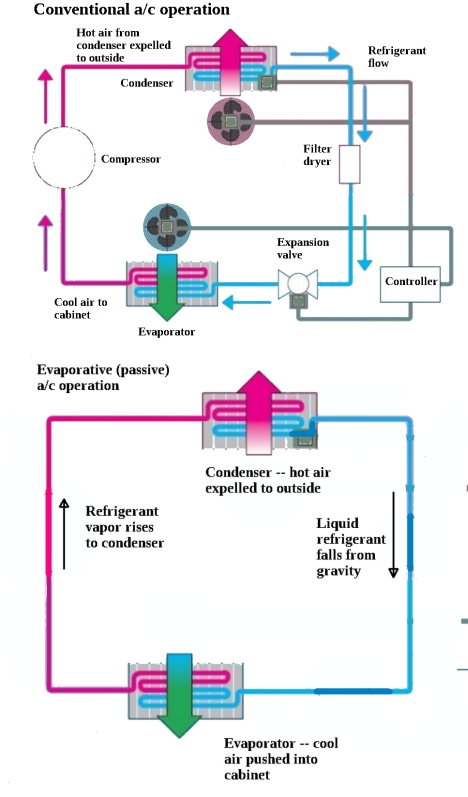

The Rittal Blue e+ combines a conventional a/c with an evaporative scheme that moves refrigerant through the coils using only gravity. Both the conventional and evaporative systems share the same condenser and evaporator coils.

Though most evaporative schemes use open air and water evaporation, the same idea can be applied in a closed system with a refrigerant. And that is the technique Rittal uses. Here, heat from the enclosure (rather than moisture) causes the vaporization of the refrigerant from a liquid to a gas. The refrigerant (R134a, the same as in the conventional a/c part of the system) is held at a pressure that enables it to be in a gaseous state at high enclosure temperatures and change back to a liquid as it gives up this heat to the air outside the enclosure.

A point to note about Rittal’s evaporative cooling technique is that the refrigerant it uses needn’t be pumped back and forth. The coils through which refrigerant pass are oriented so that the heated refrigerant gas rises, eventually reaching a portion of the coil system surrounded by cooler outside air where the refrigerant condenses back to a liquid, releasing a heat of condensation through the heat exchanger coils to the outside air. Gravity then forces the liquid refrigerant to then drip back down into the portion of the coil system in contact with the hot enclosure air. Here, the refrigerant again absorbs heat as it changes into a gas, and the cycle repeats. Thus, the refrigerant changes back and forth between liquid and gas, and travels up and down the heat exchanger tubes, with no outside mechanical help. This makes the whole scheme energy efficient.

Rittal’s term for this system is a passive heat pipe, so called because the only outside energy it requires comes from the fan that blows outside air through the heat exchanger coils to cool the refrigerant.

The Blue e+ system operation when the temperature outside the cabinet is higher than that inside. Here, the conventional a/c is active – signified by the alternating colors — while the passive system is inoperative. The passive heat pipe kicks in when the outside temperature is below that of the cabinet’s inside.

Of course, the passive heat pipe idea won’t work if the air outside the enclosure is about the same temperature as that inside. This scenario is a possibility in the industrial settings where equipment enclosures may reside. The passive heat pipe is most beneficial when the cabinet internal temperature is at least a 15ºK hotter than the outside ambient temperature. Rittal says the heat pipe will handle about 60% of the total cabinet heat load under such circumstances. Additionally, Rittal says the heat pipe won’t work in reverse; no thermal energy from the outside can enter the cabinet via the heat pipe.

In cases where the cabinet heat gets too high or the outside temperature is too hot, the conventional a/c cools most of the heat load. The conventional a/c itself is quite energy efficient thanks to its use of variable-speed drives and brushless dc motors on both the rotary compressor handling the refrigerant and on the fans pushing air through the heat exchangers.

In addition, the passive heat pipe and the conventional a/c work together during many modes of operation. The combination can keep the air temperature inside the enclosure more nearly constant and less variable than either unit working alone. To this end, the Blue e+ uses an intelligent cooling-speed regulation system that calculates the amount of cooling necessary and adjusts the fan and compressor speed to reach it. This results in significantly less thermal cycling in the enclosure and maintains a constant cold air outlet temperature. In the same vein, the cooling unit can adapt flexibly to temperature changes in the enclosure.

One other measure augmenting the energy efficiency of the a/c is a coating of nanocoating on the condenser of the cooling unit. Ceramic nanoparticles in the paint give the condenser a dirt-repellent surface. And the surface pores are permanently sealed to eliminate any submicroscopic hooks for contaminating particles which could diminish heat transfer from the condenser.

Rittal says the combination of the passive heat pipe and variable-speed controls lets the Blue e+ provide the highest seasonal energy efficiency ratio (SEER) available today for a controls cabinet cooler. Rittal thinks SEER, which considers seasonal temperature variations, is a better measure of efficiency than the energy efficiency ratio (EER) which is calculated using an assumed constant ambient temperature of 95°F.

Maintenance personnel can communicate with the Blue e+ controller using a smart phone and a near-field communications link. The phone can read out performance data and let technicians set parameters using simple plain statements in local languages.

References

Rittal GmbH, www.rittal.com

Reviewing the basics: Conventional a/c principle of operation

As a quick review, conventional a/c uses a compressor to compress gaseous refrigerant into a liquid, causing it to heat up. The refrigerant passes through an external heat exchanger (condenser), where the heat of the refrigerant dissipates to the ambient air. This cooling liquefies the refrigerant. Liquid refrigerant flows via a filter dryer to the expansion valve. Here the refrigerant is depressurized and flows through the second internal air heat exchanger inside the enclosure. Refrigerant in this heat exchanger absorbs the heat from the enclosure. The absorbed heat gasifies the refrigerant and the cycle begins again.

It’s cool to think that you can combine the conventional AC and evaporative AC systems. The fact that this combination can keep the temperature more constant and less variable than the two systems separate is great. Can homes get a system like this? I think I would like it!

it’s possible but it will work only winter season in homes, every one is like to decrease there expenses, different company provide inverter,dual inverter A/c,it is also less energy consume.