Written by Jody Muelaner

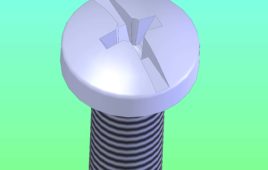

A shoulder screw is a mechanical fastener that screws into one part and provides a freely rotating pin joint connection to another part.

A shoulder screw, also called a shoulder bolt, has a shank with a larger diameter immediately below the head that “steps down” to a smaller diameter for the threaded length.

The change in diameter provides a “shoulder,” which can be firmly tightened against the part to that which it is screwed. This allows a shoulder screw to be firmly fastened to one part without clamping the other part, allowing it axial clearance.

The shank provides a smooth bearing surface for a pin joint connection between the parts. A shoulder screw may be used in conjunction with a plain bearing, such as a nylon bush, to provide improved rotation between the parts.

Shoulder screws may use different types of head. A hex socket cap head is common although standard hex heads may also be used. Shoulder screws are available in standard sizes though it is quite typical for shoulder screws to be special parts dimensioned for a particular machine. This is in contrast to most other mechanical fasteners where it is far more common for standard fasteners to be used.

In addition to the step between the shank diameter and the thread diameter, there is usually an undercut between the shoulder and the start of the thread. This undercut allows the shoulder to be screwed tightly all the way up to a threaded hole.

When a bespoke shoulder bolt is manufactured for a particular machine, the undercut may be omitted and the threaded hole may instead begin with a chamfer to enable tightening of the shoulder screw. This is generally easier to produce and may save costs.

Tell Us What You Think!