Kennametal has introduced its latest ceramic turning grade, KYHK15B, designed to deliver increased productivity and lower cost per edge in hard-turning operations. The new grade provides greater depth of cut capabilities than PcBN inserts when machining hardened steel, high-temperature alloys, and cast iron, as well as maximum tool life and wear resistance for the most…

Kennametal launches FBX Drill for faster aerospace machining

Kennametal has introduced the FBX drill for flat-bottom drilling of structural aerospace parts. The patented FBX drill delivers superior stability and up to 200% higher metal removal rates when machining high-temperature alloys, stainless steel, and other materials. The new modular drill is the critical first step in a three-part tooling concept — including the HARVI…

A replaceable drill tip that saves tooling costs and process steps

Drilling flat-bottom holes is a challenge. So is drilling on inclined or curved surfaces, or drilling into cross holes, stacked plates, castings, and other rough surfaces. Not anymore. Leveraging the success of its KenTIP FS modular drill, Kennametal has developed a unique insert geometry (FEG) that streamlines many of these types of applications and simplifies…

Kennametal introduces KCS10B for superalloy applications

Kennametal has introduced its latest turning-grade KCS10B, for nickel, cobalt and iron-based superalloys used in aerospace and other high-temperature applications. KCS10B, which features an advanced coating applied to an ultra-fine grain carbide substrate for superior layer adhesion. It delivers up to 50% greater tool life, more predictable processes, and an improved productivity when working with…

Kennametal introduces the HPX Solid Carbide Drill

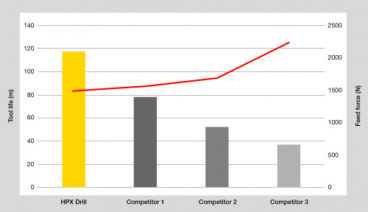

Kennametal has introduced an expansion its solid carbide drilling portfolio — the HPX drill for high-performance, large-volume drilling in steel. Designed to quickly and efficiently punch holes up to 8 x D in any ISO-P steel material, the HPX drill provides up to twice the tool life and three times the productivity compared to competing…