Scope AR announced the launch of WorkLink IoT, a platform service that enables real-time data connectivity within industrial environments for augmented reality experiences. The service enhances WorkLink, its end-to-end enterprise AR platform, with the Internet-of-things (IoT) and enabled devices and real-time data fabrics. The launch marks the first-ever offering of IoT-connected data in a no-code AR platform.

Real-time data from smart tools and a wide array of edge devices within the industrial IoT can be easily aggregated into augmented reality work instructions. Learn more about the WorkLink IoT platform here.

WorkLink IoT will become a critical component of the AR-enabled digital thread for manufacturing and field service use-cases. Now, real-time data from smart tools and a wide array of industrial edge devices can be aggregated into augmented reality work instructions.

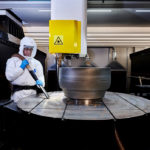

“Our customers are absolutely thrilled to integrate machine data into their AR work instructions,” said Scott Montgomerie, CEO and founder of Scope AR. “Imagine measuring the torque of each fastening operation as you build a product, with instant feedback provided to the technician in augmented reality. That data can also be sent to any manufacturing or service systems of record in real-time.”

Montgomerie added: “This completely changes the quality control and compliance landscape for our customers, offering unprecedented traceability, insights, and human error avoidance.”

WorkLink IoT is the result of a pioneering collaboration between Scope AR and Litmus Automation, a flexible and scalable edge platform for industrial IoT data connectivity. The collaboration also involved fastener expertise by Click Bond, smart tools by Atlas Copco for precision torque measurement capabilities and advanced 3D AR wearable devices, including the Microsoft Hololens 2.

“We are pleased to partner with Scope AR to provide access to all industrial data at the edge from any type of machine or tool,” said John Younes, co-founder and COO of Litmus. “Our technology allows WorkLink IoT to connect to any device in minutes, normalize the data for easy consumption, and integrate the data with the AR platform. Now customers can focus on getting value out of their data and the AR solution rather than spending time solving operational complexity since we’ve done that work.”

Click Bond president and CEO, Karl Hutter, added: “As a pioneer of advanced assembly solutions for aerospace, Click Bond recognizes the opportunity to unlock technicians’ talents using XR and IoT tools, expanding their capabilities and raising the value of their work. We are proud to partner with Scope AR in bringing this to reality.”

“Previously, customers were forced to hard-code their own data pathways or manage disparate systems in order to enable smart factory data into augmented reality experiences,” said Montgomerie. “This has limited production use cases at scale. Instead, we partnered with Litmus and built a system to allow any available edge data feed to be accessed from within our code-free AR environment, removing any compatibility or development inhibitors to scale.”

WorkLink IoT is another pillar of Scope AR’s digital thread offering, with the goal of providing real-time data to technicians and systems of record throughout the physical product lifecycle.

Tell Us What You Think!