Creative thinking in the field of kinetics has led to the development of a revolutionary fastening clamp suited to applications in a variety of industries, including assembly, verification, handling, and welding. Misati, S.L., Barcelona, Spain, has supplied industrial clamps since 1979. Their newly-developed fastening clamp line is now offered in the U.S. by J.W. Winco, Inc., a manufacturer and distributor of standard components for industry located in Wisconsin.

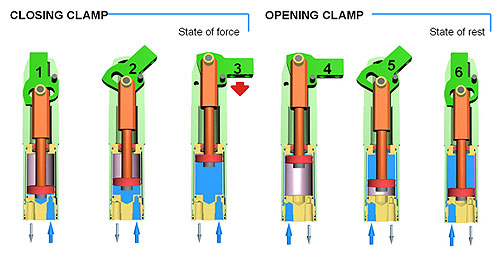

The Misati clamps exert great force with a smaller apparatus. Each clamp has a double-effect pneumatic cylinder that transmits a turning movement to the clamping arm along the shaft. Thanks to the special shape of the oblong hole, the clamp exerts high force. The design allows for a smaller diameter apparatus to generate up to 333% more force than other clamps.

These clamps are up to 42% narrower than typical clamps, so they suit applications in confined spaces. The design of the force mechanism employs a smaller-than-typical stroke that uses less air per cycle.

They use a monobloc body of machined and treated steel, which incorporates the stress mechanism and pneumatic cylinder. The built-in connections have no-flow regulators. If the application requires an extra long arm, a pneumatic cushioning option is available. Each clamp is guaranteed for five years or 20 million cycles.

Misati clamps are offered in four styles with piston lengths from 20 to 50 mm. The design of the clamp permits either front or lateral mounting with centering guide bushings. They also do not use lateral sockets, which simplifies installation even in small spaces. Clamps can be interchanged easily and may also be affixed using a collar thjat permits them to be rotated in place.

J.W. Winco, Inc.

www.jwwinco.com

::Design World::

Tell Us What You Think!