By Dr. Jody Muelaner

Clinch joining presses sheet metal together so that it joins without the use of fasteners, welds, or adhesive.

Clinch joining is also known as press-joining or clinching. It is one way to quickly and cost-effectively join sheet metal without the use of fasteners, welding, or adhesives.

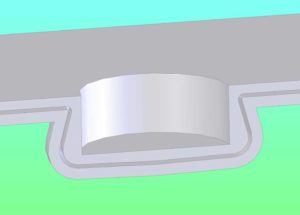

How it works: A punch is pressed through both layers of sheet metal into a die and in such a way that the sheets become locked together. However, this process means clinch joining is only suitable for ductile sheet material — typically from 0.5 to 3mm in thickness.

The shape of the punch and die used for clinching causes the sheets to flow outward at the bottom of the stroke. The resulting overhang locks the sheets together. Typically, a radially sprung die is used, which allows this expansion and the subsequent removal from the die.

The tooling can take several different forms, with propriety clinching processes developed by a number of companies. The tools can be circular or rectangular in profile and may be non-piercing or semi-piercing. Non-piercing clinching does not tear the sheet material while piercing produces slits in the material. It is typically used with rectangular tools.

Clinching is generally weaker than other methods of fastening, such as spot welding or self-piercing rivets. However, joint strength can be verified through non-destructive testing by dimensional measurement of the formed joint. For aluminum sheet, clinch joints may also have higher fatigue life than spot welds.

The main advantages of clinching relate to costs and operational simplicity. It is usually used for high-volume products, which do not require high-strength joints. Examples include household appliances, ventilation ducts, and non-structural automotive panels. Clinch joints are rarely used for visible surfaces because of their appearance.

Another advantage of clinching, when compared to welding, is that it allows dissimilar materials (such as steel and aluminum).to be joined together.

Unlike welding, clinching does not require surfaces to be treated before fastening — nor does it produce any heat effects in the parts. From a safety perspective, there are no sparks, arcs, or fumes. It usually only requires an air supply but without electrical requirements.

Tell Us What You Think!