By Dr. Jody Muelaner

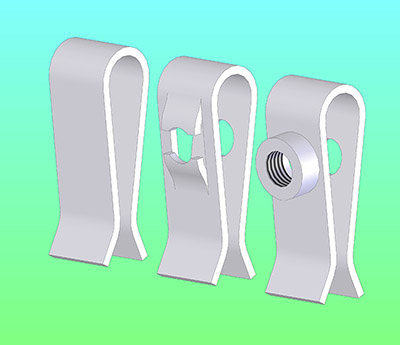

U-clips are designed to clip onto panels or sheet metal parts. From left to right: A simple U-clip, a U-clip designed to accept a self-tapping screw, and a U-nut.

U-clips are an easy-to-assemble mechanical fastener. They are normally formed from a single strip of sprung steel, bent into a ‘U’ shape to form two legs. These legs often have lead lips so that they can be easily pushed over panels and sheet components, causing the legs to open outwards. The sprung legs exert a light clamping force, retaining the clip in place. Some spring clips also have barbs to provide a more secure fastening connection.

U-clips can be used to clamp panels together, retain cables and insulation, or to provide a spring catch. They are an economical and easily reusable fastening which requires no tools. They are typically made from zinc plated sprung steel — but are also available in stainless steel, copper and bronze.

U-clips allow rapid assembly and also do not require holes, welds, screws or rivets. They can, however, be used as a form of captive nut, providing a threaded hole for the attachment of a bolt or self-tapping screw. A U-clip is fitted by placing it at a slight angle to the panel, so that the legs can be led over the edge of the panel, and then pushing the clip so that it seats squarely against the edge of the panel.

Additionally, U-Clips can form part of a captive nut, or clip-on nut, with a nut to accept a bolt or machine screw welded to the U-clip. When a U-clip incorporates a preformed thread in this way, it is normally referred to as a U-Nut or a chimney nut. Many U-clips do not have any preformed thread but are designed to accept a self-tapping screw. In this case, one leg typically has a clearance hole while the other leg has a smaller hole or bent tabs, designed to take the thread from a self-tapping screw. When U-clips are designed to accept self-tapping screws, they may also be referred to as U-nuts — but, more commonly, these are simply called U-clips.

Tell Us What You Think!