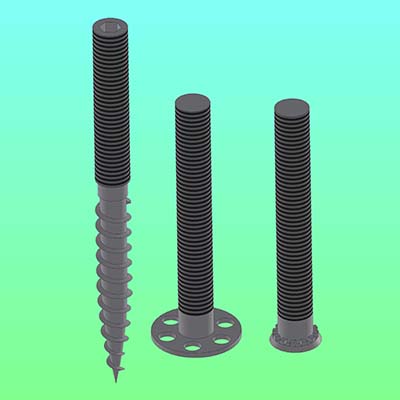

Studs designed to be attached by (from left to right): Screwing into wood, bonding into composite and swaging into sheet metal.

By Dr. Jody Muelaner

A stud is essentially just a piece of threaded bar. This often resembles a machine screw without a head, although some studs to have heads that get permanently incorporated into the part they are attached to. Studs are often designed to be permanently attached to one part, proving a means of attaching another part in conjunction with a nut. This type of stud may be welded, swaged or bonded to attach it and may, therefore, have a small head to enable this.

Other studs may have threads at both ends. In some cases, these are both intended to accept nuts — such a stud is called a stud bolt. Alternatively, a stud may have a self-taping thread at one end, intended to be permanently screwed into a part, and a machine thread at the other end to accept a nut. Some common types of stud include:

• Fully threaded stud bolt: A type of stud bolt which is essentially just a length of threaded bar. Stud or studding is also a term for threaded bar. This may be used for fastening large parts together, with nuts at each end to form a bolt. There are many other uses for this type of stud in providing an adjustable member for structures and machines. Nuts are able to be moved over a large distance along the bar while also generating a large force.

• Tap end stud bolts: These have a short length of thread at one end, designed to be screwed into a tapped hole. They then have a shank and a longer length of thread at the other end to accept a nut.

• Double end stud bolts: These have equal lengths threaded at each end, intended to accept nuts, with a shank in the middle.

• Weld bolt: These have a full-length machine thread with a thin wide head to make them easier to weld, typically to a steel fabrication, providing a permanently attached stud.

• Clinch stud: These have a small tapered head with teeth, designed to permanently swage themselves into sheet metal when tightened.

• Bonding stud: A full-length thread with a flat wide head, often with holes in the head. Designed to be bonded into composite parts providing a permanent metal stud.

• Dowel screw: These have a wood screw at one end and a machine screw at the other. They are designed to be permanently screwed into wood, providing a stud to fasten a part using a nut. Either a socket at the end of the machine screw or a hexagonal form between the two threads is used for tightening.

Tell Us What You Think!