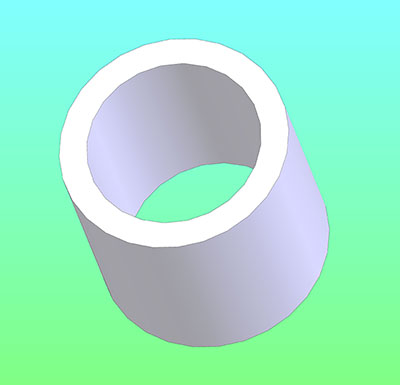

A spacer is typically a simple length of tubing which increases the distance between parts and allows a bolt to pass through the center.

By Dr. Jody Muelaner

A spacer is used to increase the distance between parts being fastened. Spacers are often a length of tube through which a fastener is inserted; a short spacer may therefore resemble a thick washer. Washers are sometimes used as small spacers. Spacers are similar to standoffs, but standoffs include a threaded shaft or hole, enabling them to be fitted without an additional fastener. These definitions are not always strictly applied and it is possible to find threaded standoffs referred to as spacers in many catalogs.

Both spacers and standoffs are commonly used within electronic assemblies. They are used to provide space for cooling airflow and provide electrical insulation. They may be referred to as PCB Spacers. Common materials for such spacers are brass, stainless steel, nylon polyoxymethylene (POM), polyvinyl chloride (PVC) and ceramics.

Most spacers have a clearance hole through which a bolt is inserted. This means the spacer does not engage with the threads of the bolt. Since the spacer cannot be directly tightened, a round outer profile is most common.

Some spacers have a hexagonal profile combined with a plain hole. These are typically constructed from a relatively soft material such as nylon or brass. They can be used in the same was as a conventional spacer but have the added flexibility that they can be threaded onto a stud or self-tapping screw, using the external flats of their hexagonal profile to apply torque. This type of spacer can, therefore, effectively be turned into a female/female standoff.

Snap-in ‘spacers’ are also available which have a sprung push fit fastener at one end and a threaded hole at the other end. These are also really a form of standoff.

Tell Us What You Think!