Written by Kim Keating, Director of Customer Success

ZAGO Manufacturing Co.

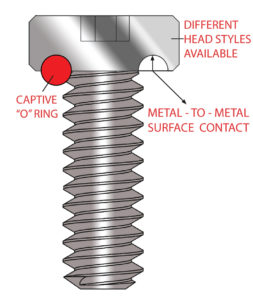

A diagram of a sealing screw.

Sealing fasteners are highly specialized fasteners that include sealing screws, nuts, bolts, and washers. These types of fasteners are used in several industries because of their unique ability to protect conventional machinery and complex equipment with high-tech properties.

For example, these components are a staple for the military and aerospace sectors, sealing critical applications such as fuel pumps of jet and rocket engines, satellite equipment, and others.

Unlike ordinary fasteners, sealing fasteners are configured with a rubber O-ring (or a rubber element) that when squeezed, permanently seals out contaminants. This can include disinfectants, oil, gas, humidity, dust, moisture, or any debris or chemicals that can damage or destroy equipment while, at the same time, preventing equipment leakage of toxins (i.e. acid leakage from lithium batteries) into the environment.

The design

Sealing fasteners are engineered with a groove under the head of the screw or the face of the nut that — when combined with a rubber O-ring and tightened — squeezes outwardly to form a 360-degree leak-proof hermetic seal.

The undercut groove ensures that the O-ring will not break or crack once the screw is torqued. The metal-to-metal contact prolongs the life of the O-ring, which stays uncompromised under pressure.

Sealing fasteners are specifically designed to withstand harsh weather conditions and extreme temperatures. Examples include when an unmanned underwater vehicle surveys the icy depths of the ocean floor or an unmanned vehicle operates in the extreme heat of the desert.

These components are also vibration and pressure-resistant, outperforming typical fasteners in highly pressurized environments. Such applications may include pneumatic pumps used in medical ventilators, pressure valves in industrial machinery, or rocket engines orbiting in space.

The benefits

Since sealing fasteners can withstand harsh weather conditions and extreme atmospheres and temperatures, these components are ideal for use in autonomous robots and drones, including batteries and sensors. Such benefits make it possible for robots to venture into environments for long periods of time and perform tasks that are dangerous for humans — such as surveilling damaged power lines, wind-turbine blades, or even collecting and transmitting critical information about climate change from the Arctic.

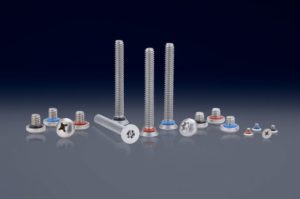

A variety of sealing screws, which are designed to seal out contaminants and prevent leaks.

Sealing fasteners are made of corrosion-resistant metals, such as stainless steel and steel alloys, titanium, or Brass and Monel. This means they can easily be cleaned and are impervious to alcohol and other disinfectants.

These sanitary benefits make these fasteners a safe choice for sealing invasive and non-invasive medical instruments and equipment, ranging from laser scopes and surgical robots to kidney dialysis machines.

Sealing fasteners are also available in different drives, head recesses and styles, and thread sizes. Rubber O-rings are offered in Silicone, Fluorosilicone, Viton, Neoprene, Buna-N, Teflon, and EPDM material.

Silicone rubber is a popular option because of its vast temperature range (62° to 204° C | 80° to 400° F) and its ability to withstand low temperatures without becoming brittle. However, it is not an optimal solution for oil resistance (Buna-N compound is resistant to petroleum-based substances).

The application

If you’re unsure when to use sealing fasteners, below are three simple questions to ask. If the answer to any of the following questions is “yes,” then sealing fasteners are an ideal choice to protect and optimize the functionality of an application or equipment.

Does your high-asset machinery or sensitive equipment need an air-tight, hermetic seal to…

- Ensure protection from possible exposure to oil, gases, liquids, chemicals, dust, dirt, moisture, saltwater, or other contaminants?

- Withstand extreme pressure, temperature and/or weather conditions?

- Prevent the seepage of pollutants leaking into the environment?

The standards

Military-grade sealing screws and O-rings that meet the requirements of the Military Standard MS3212/MS3213/NASM 82496 and are pressure-tested to 1500 psi are available through select manufacturers. This is also true of FDA-approved O-rings.

When purchasing sealing fasteners, it is important to buy from a manufacturer that’s been certified or that meets the standards of DFARS, REACH, RoHS, and DEKRA and offers NEMA-ready solutions for electrical enclosures.

Sealing fasteners are used to seal all sorts of equipment whether on land, in the air or at sea, including:

- Aircraft engines & motors

- Circuit boards

- Conveyor belts

- Data centers

- Drones and drone ports

- Earphones

- Electric charging vehicle units

- HVAC systems

- Invasive / non-invasive medical devices

- LED / smart lighting

- Night-vision goggles

- Rechargeable batteries

- Robots and co-bots

- Sensors

- 3D cameras / LiDAR technology

Tell Us What You Think!