Superior Washer & Gasket’s inventory of washers and shims are among the largest and most comprehensive in the industry. With more than 100 high-speed power presses, the company now offers Superior Premium Deliver (SPD). This means it can produce even unique or special washers with a five to seven-day turnaround.

Superior Washer & Gasket’s inventory of washers and shims are among the largest and most comprehensive in the industry. With more than 100 high-speed power presses, the company now offers Superior Premium Deliver (SPD). This means it can produce even unique or special washers with a five to seven-day turnaround.

What’s more is that Superior’s products are produced to the highest standard. All of its washers, springs, spacers, and gaskets officially meet the manufacturing requirements as set forth in the ISO-9001 Registered Quality Program.

Superior’s facilities — including one in New York and the other in South Carolina — are fully automated and computerized, enabling the company to produce washers and stampings to exact customer specifications. Its ability to control every aspect of the manufacturing process provides a wide latitude in scheduling rush orders and prioritizing emergencies.

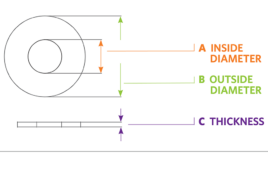

Production covers thicknesses from .0005 through .250, with over 20,000 square feet of raw material. It has access to several materials, including aluminum, brass, Titanium, Viton, and others, with new material added regularly.

The company’s in-plant machine shops can also custom-make a die to specification if it’s not already available in its wide range of dies. Superior is able to promptly fill any customer’s request and order regardless of which branch is contacted.

Tell Us What You Think!