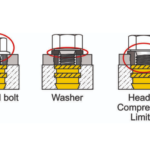

SPIROL has expanded the CL220 Compression Limiter offering by adding additional diameter and length combinations to accommodate a variety of application requirements. Compression limiters are non-threaded inserts designed to protect and prevent the over-stressing of plastic components.

The CL220 is the only standard

Compression Limiter finished with a protective coating of ArmorGalv, a zinc alloy thermal diffusion coating covered by ASTM

A1059M-08(2013). Learn more here.

The CL220’s split-seam, flexible diameter accommodates wide hole tolerances and the gap is designed so the parts will not interlock in the free state. The new limiter is intended to be installed into the plastic component after the molding process. Spring force provides self-retention within the hole.

Once installed, the CL220 provides a minimum clearance of one millimeter around the bolt diameter to compensate for misalignment.

Produced from high carbon steel, the CL220 is finished with a protective coating of ArmorGalv, a zinc alloy thermal diffusion coating complimented with two sealers that provide 1000-plus hours of salt spray protection for highly corrosive applications such as automotive, marine, mining, and industrial manufacturing.

Additional benefits of ArmorGalv include no insignificant surfaces as the entire inner diameter (ID) of the Limiter receives full coating and protection. Additional benefits include:

- Zero risk of hydrogen embrittlement

- Will not reduce fatigue strength of material

- Uniform deposition of coating on all surfaces

- Anti-galling characteristics similar to cadmium

- No flaking, peeling, or blistering

- Hard and highly abrasion resistant @ 37-42 HRC

- Slightly porous surface will retain paint and other coatings

Rated for use up to ISO Class 8.8 bolts, the new CL220 Compression Limiter offers the widest range of standard diameter and length combinations to accommodate a variety of application requirements.

Tell Us What You Think!