Schreiner ProTech, a global innovator for the automotive and engineering-based industries, has introduced a new version of its PCS HighProtect pressure compensation seal.

Schreiner ProTech’s newest PCS HighProtect pressure compensation seal offer a membrane that protects electronic housings against damage.

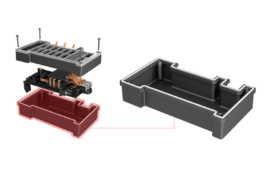

During the EV charging process, the electric current generated leads to high temperatures in the charging plug and socket area. These temperature fluctuations result in pressure differences in the electronic housing. Schreiner ProTech’s PCS HighProtect pressure compensation seal comprises a membrane that protects electronic housings against potential damage.

The PCS solution can yield additional benefits as well. In certain installation scenarios, such protection films can dampen the “noise” that occurs when the cover contacts a rear panel. Automotive manufacturers require high-steam jet resistance in the charging socket area. Here, PCS HighProtect’s flat design helps address these requirements while providing engineers with ample design freedom. This is important since, until now, snap-fit versions leaving minimal scope for design have frequently been used for EV charging pressure compensation.

PCS HighProtect seals also are lighter in weight and offer higher processing cost efficiencies compared with conventional snap-fit solutions. Because the e-mobility sector frequently entails smaller vehicle volumes, the flexibility to manufacture several types of charging sockets on one line is crucial to economic viability.

To this end, Schreiner ProTech offers customized specialty manufacturing cell solutions that enable several charging socket versions to be produced and processed on one line. For PRESS RELEASE Seite 2 von 2 example, the company’s EV production team can advise on position and installation circumstances including protective edge and cavity design.

Tell Us What You Think!