Schreiner ProTech, a global provider of developing and manufacturing services, has developed a nameplate-integrated pressure compensation seal (PCS) solution for actuators produced by Küster Automotive, a prominent auto parts supplier.

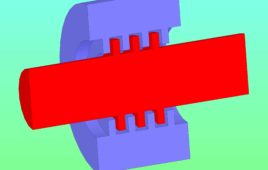

The new PCS solution is applied to the company’s reliable, often customized actuators — motion-control technology units that convert electrical signals into mechanical motions, or prompt changes to critical variables like pressure and temperature.

The new PCS solution is applied to the company’s reliable, often customized actuators — motion-control technology units that convert electrical signals into mechanical motions, or prompt changes to critical variables like pressure and temperature.

As a systems supplier, Küster draws on more than 40 years of experience in mechatronics. Its actuators are used, for instance, to reduce noise and emissions in exhaust systems, as well as for heat recovery. Its acoustic flap actuator (AFA) is used in a vehicle’s tailpipe area, providing back pressure control that enhances acoustic performance without necessitating large mufflers.

The PCS seals from Schreiner ProTech are used to control the pressure compensation in an actuator’s electronic housing, as well as to mark the component. With an integrated nameplate, the seals combine marking and venting functionalities, optimizing process costs, and efficiencies.

“Due to the integrated label, the edge of the pressure compensation seal is provided with optimal technical protection, which provides us with the in-process benefit of needing only one application step and everything being supplied by a one-stop shop,” says Thomas Schmidt, who is in charge of Pre-Development at Küster Automotive. “In our operation, the product ID is already allocated by the workpiece carrier. Afterwards, the label is individually printed and subsequently applied using Schreiner ProTech’s application device.”

Tell Us What You Think!