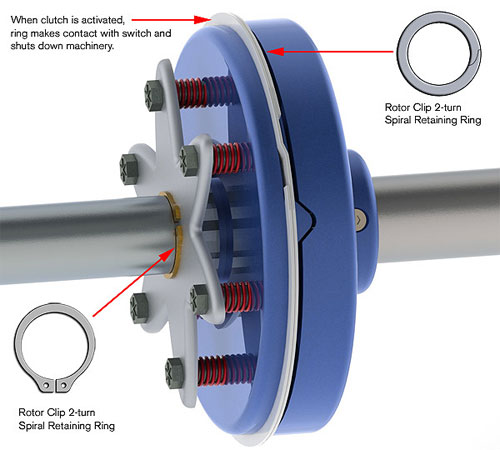

Overload Clutches, other wise known as torque limiters, are an automatic device that protects machinery from damage because of an overload. Overload clutches utilize a switch, such as a limit switch mounted in close proximity to a plastic detector plate carried by the overload clutch. If an overload occurs the clutch expands axially moving the plastic detector plate into the switch turning off the equipment avoiding damage to the product and machine.

The introductions of magnetic proximity switches are becoming more widely used in conjunction with overload clutches. A proximity switch is magnetic; therefore the detector plate no longer has to make physical contact with a switch. A small amount of movement will set off the overload clutch and detector causing the machine to switch off. However the detector plates are commonly made of plastic which are not magnetic so new ones made out of metal or steel have to be made in order for the plate to be “seen”. Making these new plates cost money, adds weight and inertia that is dangerous to the machine.

The solution, a pre-cut groove around the edges of the plastic detector plate so that a spiral-retaining ring can be fit securely around the plastic detector plate. The spiral ring is cost effective, does not add more weight or inertia to the machine and can be used in conjunction with magnetic proximity switches.

A Rotor Clip SH ring can also be used to locate the pressure plate on the shaft, eliminating the need to machine a shoulder or rely on other costly fastener methods to perform the same function.

Rotor Clip

www.rotorclip.com

www.rotorclip.com

Very useful piece of equipment which is quite durable too. I am amazed at how they have imagined to create this thing. Some people just have simply brilliant minds to be able to think about these things. – http://www.non-ferrousfastener.com/