If variety is the spice of life, Manuel Martinez has experienced his fair share throughout his career. He’s worked in several roles as an engineer — in quality, product design and development, and management — in three different countries during the last 16 years. He’s worked in tooling, chemical bonding, and mechanical fastening.

Manuel Martinez, Senior Product Development Engineer with ARaymond Network.

What has remained consistent is the company he’s worked for, ARaymond, a global expert in fastening and assembly solutions.

“If I’m fortunate enough, I hope to spend my entire career with ARaymond…until retirement,” Martinez shares. “It is a company that puts its employees first and that has allowed me to challenge myself in new roles over the years.”

He’s currently a senior product development engineer in ARaymond’s Michigan facility, primarily designing fasteners for some of the company’s top automotive OEMs. But Martinez began his career in his home country of France, where ARaymond is headquartered.

“Aside from a co-op job during university, ARaymond has been the only company I’ve worked for though I never planned this career path,” he admits.

Initially, Martinez was interested in IT and computer science, but his father convinced him the market was saturated and an unwise career path for a successful future.

“Little did my father know at the time, considering the IT world today,” laughs Martinez. “But what he said was enough to change my mind. My father worked in a mechanical field, so I decided to follow in his footsteps and took mechanical engineering.”

Martinez went to the University Joseph Fourier in Grenoble, France, and shortly after graduating with his degree joined the ARaymond Network as a quality engineer. At first, he worked on general product testing and lab reports. The company designs and manufactures plastic and metal assembly solutions for several industrial markets, including the automotive sector.

“After about a year, I had the opportunity to move to the engineering department to work on new fastener designs,” he says. “Then, a couple of years later, I joined a new division for the company in Pune, India. It was a chance to become a project and engineering manager, overseeing parts design and development and tooling.”

One example of the many components Martinez has designed as an engineer at ARaymond — a bonded plastic clip.

The work focused on plastic injection tooling for plastic fasteners. India is also where Martinez learned to speak English, which would eventually support his role in America. He spent two years in Pune, which he enjoyed despite the initial culture shock.

“There was a lot to learn, including a new language, which for me was great,” he says. “I really liked the people there. And workwise, it was a big leap forward for my career. At the time, it was a start-up, so with that, you’re wearing multiple hats and it meant a lot that I was trusted with the responsibility of those roles.”

Martinez oversaw the tooling and engineering teams and was responsible for the component designs and costing for the company.

“I probably would have stayed in India longer, but it was not conducive to my personal relationship then…and, honestly, this is where ARaymond stands out as an employer because they worked with me to find another position.”

Always one for learning and new experiences, Martinez accepted another position abroad — this time as a technical project manager in the U.S. with ARaymond’s bonding division.

“I was still open to ex-patriation and working in another country because it’s so novel and mind-opening, so to speak. I moved to Rochester Hills, Michigan in November of 2011, and it was cold,” he laughs. “Another culture shock although I did grow up in the Alps.”

ARaymond’s bonding division was also a new experience for Martinez although his engineering skills were certainly helpful. The company offers a tailored bonding solution for the automotive industry and offers adhesives for the white goods market and other industrial products.

“Bonding is not simple. Adhesive products involve several parameters and performance metrics, but this is where the quality engineering aspect of my experience proved useful. There was a lot of lab testing and process design to ensure the ideal solution,” he says. “We wanted to provide a full service in terms of bonding applications. It was very interesting and very challenging.”

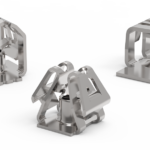

Busbar holders are another example of the vast product design capabilities and offerings available at ARaymond.

One challenge when working with chemicals is the varying parameters. Adhesives require preparation and cure times. This mindset and focus are somewhat different from the speed and precision of mechanical engineering.

Martinez enjoyed the diversity while learning new elements of fastening and project management. He was able to draw on previous skills as a manager and was involved in equipment development and plant commissioning for customers.

“Particularly in the EV and automotive sector, there are times when drilling a hole for a mechanical fastener would compromise the integrity of the material. A vehicle’s windshield is a good example. This is when bonding solutions offer an important alternative,” he explains. “But other times, adhesives work with mechanical fasteners to secure a strong bond. There’s a place for both types of fastening and sometimes that’s even together.”

After about seven years, Martinez craved that spice of life again and asked management for some variety. In 2018, he focused on product development for new electric vehicle OEMs.

“Before the pandemic, I spent time at new manufacturer’s design offices, developing fastening solutions for the latest EVs,” he shares. “This was ideal because we were, essentially, designing fasteners at the same time as the vehicles.”

Too often, fasteners are one of the last components considered in an application. Martinez says considering the fastening components during the design stage of an assembly is critical for more than one reason.

“And the earlier the better, so we can integrate the fastener within the design instead of after the design,” he advises. “It’s also then often possible to find a less costly solution and, sometimes, we realize the fastener can do more than originally expected.”

This might mean fewer components are required or lead to a more economical or lightweight solution. Lightweighting is critical, particularly for EVs where heavier components mean more battery power is necessary on the road.

“Ultimately, good fastening — whether chemically or mechanically based — means a good end product,” he adds.

Today, Martinez is in another new role, serving as senior project development engineer since 2021. He’s still based in Michigan and working with some of Detroit’s top conventional automotive OEMs.

Martinez spent part of his career developing products for electric vehicles, such as this pass-through for battery pack.

“I had a son in 2020 at the height of Covid, but fortunately all went well. And then, I had a daughter last year, so I needed more home time. The work with EV OEMs was fast-paced and extremely demanding, though I fully enjoyed it.” Again, this is where ARaymond was accommodating and found him a new position within the company.

Martinez is still busy but has been able to find more balance and integrate experiences that are important to him.

“I’ve recently had the chance to mentor a few new engineers within ARaymond, which I loved,” he shares. “I’m trying to pass on some of my experiences and lessons learned where useful.” And one of these lessons has nothing to do with engineering or fastening.

“For me, one thing that’s held true is the importance of communication. It’s important to respond to emails or follow up with messages in a fast and efficient manner. You want others to know you’ve heard them and that they are important to you…even if it takes you a while to find all the answers to their questions. Let them know you’re looking into their request.”

Learning how to effectively connect and communicate with clients and co-workers is certainly one key aspect of a successful business.

His goal for the future: “Given many years with ARaymond and the multiple positions I’ve held and experienced, I have the knowledge to help new engineers, whether that’s mentoring, sharing insight, or brainstorming new ideas with them. I want to continue to provide support.”

Manuel, congratulations on a promising career and consistency really makes all the difference to maintain this discipline is not easy at all. Very nice contents.