PennEngineering, company and global manufacturer of mechanically attached fasteners, announced the opening of a new office in San Jose, California.

Located in the PacTrust Business Center, the new facility expands the company’s presence in the Bay Area and provides a growing, local customer base with greater access to direct local resources, including engineering support and product testing.

Located in the PacTrust Business Center, the new facility expands the company’s presence in the Bay Area and provides a growing, local customer base with greater access to direct local resources, including engineering support and product testing.

“As a result of the continuing growth in the industries we serve, many with global headquarters in Silicon Valley, it was important for us to establish a permanent local presence here that allows us to easily collaborate directly with our customers and offer the critical services and capabilities they’re looking for in a fastening solutions partner,” shared Greg Swafford, VP of Sales (Americas) for PennEngineering.

In addition to corporate space, the San Jose location features a testing lab dedicated to engineering support and comprehensive testing services for the PennEngineering portfolio of fastening solutions, including brands such as PROFIL, PEM, ATLAS, and SI.

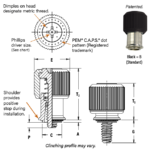

As a part of PennEngineering’s mechanically attached line of fasteners, PROFIL high-performance fasteners are permanently and securely attached to metal parts or panels by means of a riveting, piercing, or pressing process. The company’s PEM brand of fasteners use self-clinching, broaching, flaring, weld, or surface-mount technology to provide strong, reusable, and permanent threads and mounting points in thin sheet metal, P.C. board materials, and other ductile or non-ductile thin material.

The ATLAS blind threaded inserts (also known as rivet nuts or blind threaded rivets) provide strong and reusable permanent threads in sheet materials where only one side is accessible for hardware installation. Additionally, PennEngineering’s SI brand inserts employ press-in, molded-in, or heat/ultrasonic installation methods to provide strong, reusable, permanent threads in plastic.

“Our new location not only provides our customers with valuable local engineering support but also gives them flexibility to test products with our team here in the lab. We can assess insertion capabilities for most of our standard products and also conduct a wide range of other testing services to determine the safety, compliance, and application suitability of their parts,” said Travis Moore, western regional manager with PennEngineering.

Tell Us What You Think!