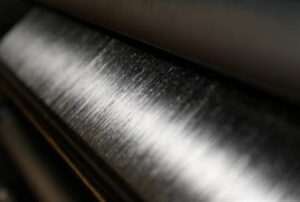

Solvay introduces LTM 350, a next-generation carbon fiber epoxy prepreg tooling material designed to deliver significant time and cost savings for the industrial, aerospace, automotive, and race car markets.

Solvay’s new carbon-fiber epoxy prepreg tooling material is designed to offer significant time and cost savings for the aerospace and automotive industries.

The carbon fiber epoxy tooling material offers a fast, low-temperature cure cycle (three hours at 60° C) and can be cured at temperatures as low as 45° C with an extended post-cure. Tools built from LTM 350 can be continuously cycled at temperatures up to 150° C delivering highly accurate composite parts.

“Our LTM product portfolio has a track record in delivering high-performance composite structures where lower cure temperatures and short manufacturing times are key,” says Greg Kelly, head of Product and Asset Management for Solvay Composites. “Building on this expertise, LTM 350 represents yet another innovative epoxy prepreg that demonstrates our continuing commitment to help OEMs, sub-contractors, and tool builders in the composites industry achieve ambitious productivity targets.”

As a low-temperature prepreg with user-friendly tack, drape, and handling, LTM 350 was designed to enable the shortest possible lay-up times while providing the highest-quality surface finish — setting new standards in cost-efficient composite tooling.

This tooling prepreg has been engineered to support the construction of both small complex and larger composite tools. It’s targeted at autoclave applications, but can also be used out-of-autoclave.

Available in optimized formats for both surface and bulk plies, LTM 350 takes advantage of a 1-5-1 lay-up (surface to bulk plies ratio) saving both valuable time and costs versus a more traditional 1-8-1 format.

As a global provider in materials, chemicals, and solutions, Solvay brings advancements to planes, cars, batteries, smart and medical devices, and more to solve critical industrial, social, and environmental challenges.

Tell Us What You Think!