Miller Electric Mfg. LLC, a global manufacturer of arc-welding equipment, offers the Millermatic 355 — proving users with power, precision, simplicity and versatility. This machine offers MIG and pulsed-MIG welds in mild steel, aluminum, or stainless in thicknesses from 22 gauge to 1/2 inch.

The Millermatic 355 can operate on single-phase or three-phase AC power — so it works anywhere operators need it to.

“The new Millermatic 355 delivers power, precision, simplicity and versatility in a compact power source for more applications,” says Chris Roehl, product manager, Miller. “Plus the machine’s advanced features make it easy for welders of any skill level to be productive and get great results.”

With high-amperage output and a long duty cycle, operators can make longer welds without stopping. The pulsed MIG capabilities allow operators to reduce heat input for better results on stainless steel. This means there’s a decreased risk of distortion or burn-through on thin metals and reduced spatter on all materials — resulting in less time spent on post-weld cleanup.

An industrial, four-drive-roll, wire-feed system ensures consistent delivery of all wire types and diameters at all speeds. And the Millermatic 355 is compatible with push-pull guns, for smooth feeding of aluminum wire.

The Millermatic 355 also has multiple features to help welders of all skill levels get more work done. For example, the Auto-Set Elite has pre-defined weld settings to increase ease of use and ensure that the job is done correctly for operators of all skill levels. This is available for both the MIG and pulsed MIG processes with the ability to fine-tune settings. Users can set the weld parameters by selecting the wire and gas type, wire diameter, and material thickness.

The program mode allows for easy save and recall for those ideal or favored weld settings. This ensures greater productivity by eliminating the need to manually set or change parameters. (Simply tap the gun trigger to select the program.)

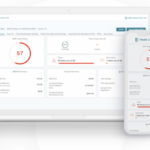

Additionally, an easy-to-understand interface with seven-inch color LCD display ensures proper machine setup and parameter selection, reducing setup time and increasing weld time. This includes:

• Quick-access backlit Auto-Set and Pulse buttons above the LCD display illuminate when active

• Soft-key buttons below the display change function depending on which screen is displayed. Makes setup or change quick, easy and intuitive

• Large text for easier readability

• Intuitive connection setup images

• Full troubleshooting descriptions versus help errors and look up codes

Features

• Compatible with push-pull MIG guns. Increases productivity by allowing the use of 12-inch wire spools versus a spool gun’s 4-inch spools. Reduces downtime changing wire spools.

• Auto-Gun Detect automatically adjusts voltage, wire speed and timers for faster switching between MIG, push-pull and spool guns.

• Single or three-phase input power provides versatility to use any North American power (208, 240, 460, 575 V).

• Input voltage selection switch located in the wire drive compartment provides the ability to manually switch input voltage. An error message will be displayed if the wrong input voltage is used.

• Generator compatible. The Millermatic 355 will be able to operate and provide full output when powered by generators with 19,000-watt (19 kW) output or higher. Limited output will occur when used with smaller generators.

Tell Us What You Think!