The laser welding machine market value is set to grow by U.S. $373.97 million, progressing at a CAGR of 4.73% from 2021 to 2025, as per the latest report by Technavio. The benefits of laser welding compared to conventional welding are driving the laser welding machine market growth. Although the requirement for skilled labor might somewhat impede this growth.

One of the key advantages of laser welding is its ability to automate the welding process, which increases overall production rates. Although laser systems are typically more costly than conventional methods, savings is gained through higher production and lower reject rates. These can nearly nullify the costs incurred during the purchase of the laser welding systems.

To learn more or download a sample of the report, click here.

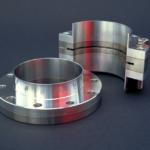

Currently, laser welding is used in several fields. This includes precise micro-welding of medical devices, small-scale manual welding in the dental and jewelry industries, and automated laser welding in the automotive and heavy manufacturing sectors.

There are advantages to laser welding over TIG, MIG, and spot welding, including:

- Weld strength: A laser weld is narrow with an excellent depth-to-width ratio and higher strength.

- Heat-affected zone: The heat zone is limited and, thanks to rapid cooling, the surrounding material is not annealed.

- Metals: Lasers successfully weld carbon steel, high-strength steel, stainless steel, titanium, aluminum, precious metals, as well as dissimilar materials.

- Precision work: The small, tightly controlled laser beam permits accurate micro-welding of miniature components are possible.

- Deformation: Parts have a minimal deformity or shrink.

- No contact: There’s no physical contact between the material and the laser head.

- One-sided welding: Laser welding can replace spot welding requiring access from one side only.

- Scrap: Laser welding is controllable and generates low volumes of scrap.

Challenges

Labor is the highest cost-consuming component of welding. The lack of a skilled workforce is fast becoming a major concern for the global laser welding machine market, affecting the U.S., India, and China.

According to the American Welding Society (AWS), the U.S. fabrication industry has a shortage of 290,000 skilled welders, and this skilled workforce shortfall is not just restricted to America. The average age of welders in Australia and the UK has now surpassed 55.

Additive manufacturing and welding

By using additive manufacturing, it’s possible to manufacture products with complex geometries that would be difficult to achieve through conventional manufacturing techniques. In addition, with additive manufacturing, material use can be optimized and wastage reduced. In the conventional manufacturing process, excess material is removed, which is later melted and reused, adding to the cost.

Additionally, the use of additive manufacturing eliminates certain manufacturing processes, such as cutting, bending, welding, and casting. This poses a risk to the global laser welding machine market. However, additive manufacturing cannot be used for all applications. For example, it’s difficult to produce large single parts using additive manufacturing, as the fabrication speed is slower than that in traditional techniques. Moreover, professional-grade 3D printing machines are expensive, which can also limit their adoption, particularly in small and medium business enterprises.

Although additive manufacturing can pose a threat to the welding process, it cannot replace welding completely.

Markets

The construction industry is expected to grow during the forecast period, owing to factors such as urbanization, increased spending on infrastructural development, and affordable housing projects. These projects will the laser welding machine market growth.

This report offers:

- CAGR of the market during the forecast period 2021-2025

- Detailed information on factors that will assist laser welding machine market growth during the next five years

- Estimation of the laser welding machine market size and its contribution to the parent market

- Predictions on upcoming trends and changes in consumer behavior

- The growth of the laser welding machine market

- Analysis of the market’s competitive landscape and detailed information on vendors

- Comprehensive details of factors that will challenge the growth of laser welding machine market, vendors

Tell Us What You Think!