Written by Jody Muelaner

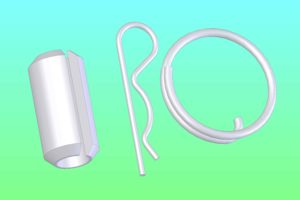

A selection of sprung fasteners that act as springs to provide secure fastening. From left to right: a roll pin, an R-clip, and a circle cotter.

Elastic deformation is central to prevent loosening in most types of fasteners. This is most obviously the case with spring pins, spring clips, and spring washers.

Sprung fasteners, such as R-clips and circle cotters, allow rapid toolless assembly and disassembly while providing secure connections. These types of fasteners require significant elastic deformation to properly insert into position — most commonly through a radial hole in a shaft.

Once in position, they exert little or no force due to elastic deformation. When the part that these components secure moves, it typically acts against them in an entirely different direction. But this does not affect these fasteners’ sprung property. For example, a wheel moving along a shaft is prevented from coming off the end of the shaft, thanks to an R-clip. The wheel acts to sheer the wire of the R-clip. However, it does not open the clip out in the way required to remove the clip from the shaft.

Such types of clips effectively resist vibrations as between each vibration they simply spring back into their original position.

Spring pins, such as roll, slotted, and dowel pins, are driven into holes smaller than the free diameter of the pin. This causes it to deform elastically as its diameter is reduced and a radial reaction force acts between the surface of the pin and the hole. The resulting friction holds the pin securely in the hole. But this is entirely dependent on the pin acting as a spring.

Although less obviously, threaded fasteners and cotter pins also rely on elastic deformation to securely fasten themselves in place. As these fasteners are tightened, elastic deformation produces reaction forces normal to the contact faces. These forces have a component that acts to unscrew the fastener or squeeze out the wedge. However, they depend on the pitch being such that the friction force is greater than this loosening component.

Vibrations can cause the friction force to cycle between high and low states, allowing a threaded fastener to gradually work loose in very small increments. A sprung washer can be used to provide a more consistent friction force within the threads, preventing this loosening.

Tell Us What You Think!