Watch a comparison test between plain washers and eccentric lock washers in this video.

Eccentric lock washers are washers that can be combined with commercially available hex nuts to prevent screw loosening. These washers, which are available from NBK, require no special tools for fastening. This means they are as easy to use as spring washers or flat washers.

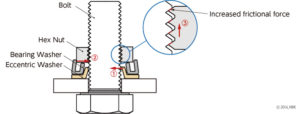

In terms of design, these components consist of a bearing washer and an eccentric washer. When the eccentric washer is wedged into a bolt, the bearing washer changes the commercially available hex nut into an anti-loosening nut.

This is based on the locking principle, which exerts the loosening prevention effect.

The locking principle

① By tightening the hex nut, the eccentric washer wedges into the bolt.

② The bearing washer presses the hexagon nut into the bolt.

③ As the bearing washer pushes the hexagon nut, the frictional force between the hexagon nut and the bolt increases, preventing loosening.

The high-performance of these loosening-prevention washers has been tested by Junker and NAS vibration tests.

The high-performance of these loosening-prevention washers has been tested by Junker and NAS vibration tests.

The benefits

Here are four benefit of using eccentric lock washers:

1. Easy fastening. The hex nut can be tightened by hand until tightening force is generated, then use a wrench to tighten.

2. Transforms hex nuts. Commercially available hex nuts, essentially, transform into anti-loosening nuts when used in combination with eccentric lock washers.

3. Works with fine threads and left threads. These washers can also be used with fine threads and left threads.

4. Easy to replace. Eccentric washers are the same height as commercially available spring washers and flat washers, which means they are compatible and easily replaceable.

View the product details here.

NBK

nbk1560.com

My “TRIX” construction set (similar to Meccano) as a 6-year old in 1940 had eccentric washers between the two halves of the wheels. (And a little SUPERB electric motor, rotating inside a magnet.