Global technology and engineering provider Emerson will exhibit advanced automation solutions at Hannover Messe, one of the world’s largest trade fairs. This year, the event takes place April 17th to 21st.

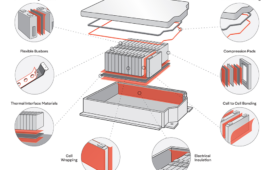

The Branson GSX Ultrasonic Welding Platform is an intuitive joining solution, designed to optimize and ensure quality welds, helping manufacturers meet project timelines and deliver ROI. Learn more about it at Hannover Messe.

During the event, Emerson experts will show attendees how to access and harness critical data of their machines, production lines, or their full production plant.

Through live demonstrations and visioning sessions, visitors (to Hall 6, Stand C57) will learn how using these technologies to get essential insights will help them drive continuous improvement throughout their operations — making processes more productive, smarter, and more sustainable.

One of the many machines on demo at Hannover Messe will include the Branson GSX-E1 ultrasonic welder. The advanced automation systems it enables can support manufacturers in improving efficiency and reaching their sustainability goals.

The GSX-E1 ultrasonic welder offers controls that automatically monitor critical weld parameters in real-time, delivering actionable performance and diagnostic data to determine overall equipment effectiveness (OEE), enable traceability, and optimize maintenance.

Additionally, the welder’s encryption technology ensures data integrity and security. Compared to joining techniques like heat sealing, adhesives or mechanical fasteners, ultrasonic welders like the Branson GSX-E1 use less electricity, require no consumable materials, and yield less waste — cutting assembly-line carbon footprints.

Learn more about ultrasonic welding here.

Tell Us What You Think!