For many years as a locally competitive tennis player, David Glass carried an adjustable wrench in his tennis bag, to bring the net cord tension into a more playable range without knowing exactly how tight the net should be.

After attending a college tournament, and noticing the variability of the net tensions, Glass approached the University of Tennessee tennis program and found an enthusiastic audience for controlling net tension. Research showed that both the international and U.S. tennis associations had been looking for a compact, accurate, durable, and inexpensive method to measure the net cord tension so that all courts at a facility play the same. The net cord tension has significant effect on the playability of a ball that strikes the cord: too tight and the ball bounces high and possibly out of the court; too soft and the ball just “bloops” over the net or back to the hitter. Net tension was the last variable remaining to be controlled, and it needed a “just right” setting.

The spring for net cord tension had to be strong enough to support a 550 lbf static load and rugged enough for year-round use in a variety of climates.

The compression spring that is internal to the device’s 6 in. housing had to withstand static loads up to 550 lbf, and still fit within a 1 in.2 tube while indicating the tension on a toothed nylon thrust washer through a slot in the housing. The washer had to remain square to the housing throughout the compression range, so the closed-and-ground ends were a must. It would be outdoors year-around, subjected to snow, rain, desert sand, and salt air, and must be repeatable for years. Searches and design conversations with Lee Spring Co. turned up a Hefty Die Spring with those characteristics and a spring rate that would allow reasonable visual resolution of the tension settings.

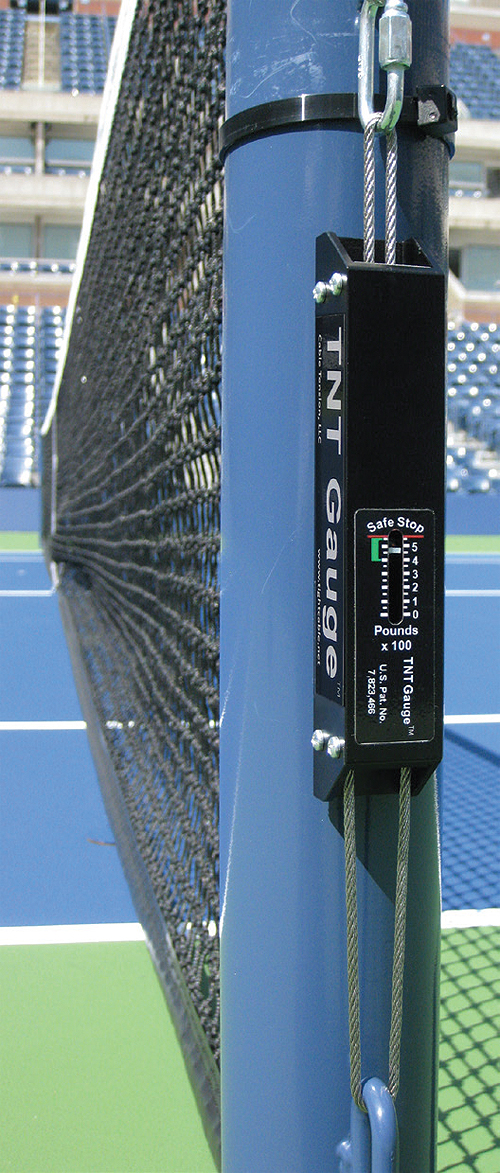

With the spring selected and prototypes revised, the Tennis Net Tension (TNT) Gauge was born. The first production units were used in college matches and early rounds of the NCAA tournament in 2011, and had their first pro experience at the Atlanta ATP event that year, where Brad Gilbert of ESPN recognized the actuality of standardized nets on the air. The Western+Southern in Cincinnati installed them on all their competition courts, and the US Open tried two Gauges on outer courts in 2011, before buying them for all the courts including Arthur Ashe Stadium beginning in 2012.

Working with the regulators of tennis as a member of a Net Tension Task Force, Glass and the TNT Gauge have provided the working solution to the net tension variable. In January 2015, the USTA Friend at Court, the manual for competitive tennis used by tournaments and officials, will recommend use of a net tension device to hold 400-450 lbf tension on all the courts at a tennis facility, with all the courts ±25 lbf of each other. This narrowly defined window was impossible to measure before the TNT Gauge.

The TNT Gauge was joined in 2013 by the Tight Right Gauge for volleyball, and is making a similar impact on the standardization of the volleyball net.

The TNT Gauge has been joined in 2013 by the Tight Right Gauge for volleyball, and is making a similar impact on the standardization of the volleyball net too, through exclusive distributorship by Sports Imports. The same Lee Hefty spring supports both sports’ nets, and there have been no hardware failures after hundreds of volleyball matches and thousands of tennis matches over three years of continuous use indoors and out.

Lee Spring Co.

www.leespring.com

Tell Us What You Think!