Auto Bolt is an American cold-heading bolt manufacturer with more than 70 years of experience in quality bolt-making. The company specializes in low-to-high volume, high-performance, and commercial fasteners for many industries including the automotive sector and many others. Auto Bolt recently announced that it has received the International Automotive Task Force’s certification, IATF 16949. The…

What are twin nuts and how do they function?

Written by Jody Muelaner A twin nut is a type of split nut that resembles a regular hex nut cut into two pieces for quick assembly and rapid adjustment. The nut is split into two halves along a plane that passes through the axis of rotation. This allows the female thread to be opened up…

Valley Forge & Bolt introduces new high-temperature Maxbolt

Valley Forge & Bolt, an American manufacturer of load-indicating fasteners, launched the new High Temp Maxbolt. This reliable component can operate in temperatures up to 650° F for nearly limitless applications and with proven performance in extended high-temperature run times and thermal cycling. With an accuracy of +/- 5%, compliant with ASTM F2482, the High…

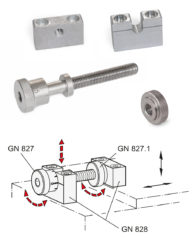

JW Winco’s new fasteners simplify repeated positioning operations

It’s often necessary to carry out repeated positioning operations on production machines and mechanisms — and as simply and reliably as possible. For secure adjustments and the quick-changing of mechanisms or tools, JW Winco now offers three new parts that complement each other: 1. Stainless steel adjusting screws, with an adjustment scale 2. Matching bearing…

Hex Technology device provides real-time feedback on achieved bolt loads

Better craft personnel performance and lower site maintenance costs are now just a “click” away, thanks to CHUCK, the new Bolting Data Unit from Hex Technology. CHUCK lets craft assembler trainees see the unseen by showing them readings for the bolt load achieved when torque is applied to an application. This lets the essential, but…

What are J-nuts and how do they work?

Written by Jody Muelaner J-nuts are a type of clip-on nut, similar to U-clips or U-nuts. Unlike U-nuts, however, J-nuts have one leg that’s shorter than the other. Other types of clip-on nuts include cage nuts and S-nuts. The advantage of J-nuts is the ability to quickly and easily attach to sheet metal parts or…

Samples now available for the ForeverLok design

Multi Piece Fastener has announced that samples are now available for the ForeverLok design, which has been vigorously tested to ensure its strength and performance. These samples are in the intended design configuration, offering a recessed nut configuration (instead of the capped version used in testing). All other aspects are identical to the tested version.…

When are rivet nuts an ideal choice for an application?

Article compiled by Industrial Rivet & Fastener Rivet nuts are internally threaded fasteners that are anchored from just one side of a workpiece or application. They’re an excellent component to use to add strength to thin materials, which is particularly important as the manufacturing trend is moving toward thinner and lighter substrates — such…

Automating the “impossible” bolt with an over-sized captivated washer

Visumatic designs and builds automatic feeding and driving equipment to install screws, nuts, bolt. The company recently delivered on an automated fastening promise to a metal stamping manufacturer. The end-user for this project asked the Visumatic team to develop a value-added product by producing a completed assembly instead of the loose parts. This application required…

GEARWRENCH launches new Bolt Biter lug-nut extraction sockets

Building on the success and popularity of the original Bolt Biter Extraction Sockets launched last year, GEARWRENCH is unveiling the latest addition to the family — the Bolt Biter lug-nut extraction sockets. The new tool use the same technology that made Bolt Biter a hit but now apply it specifically to removing worn or damaged…