The American Society of Mechanical Engineers (ASME) recently published an updated standard that includes language specific to additive manufacturing or 3D printing. The new, “Y14.46 Product Definition for Additive Manufacturing” standard identifies features unique to 3D printing and outlines how they should be communicated and documented.

The American Society of Mechanical Engineers (ASME) recently published an updated standard that includes language specific to additive manufacturing or 3D printing. The new, “Y14.46 Product Definition for Additive Manufacturing” standard identifies features unique to 3D printing and outlines how they should be communicated and documented.

The language is based largely on research by the National Institute of Standards and Technology and is intended to clarify terms, potentially encouraging greater adoption of additive manufacturing.

Previously, there was a lack of consensus on how to convey and discuss certain aspects related to 3D printing’s capabilities, affecting communication between different organizations. This potentially created a barrier to more widespread use of the technology.

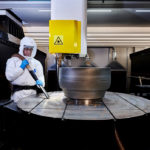

For the fastener industry, industrial 3D printing services can provide a streamlined and more efficient method of developing certain parts, including uniquely shaped fasteners and prototypes.

The new ASME guidance could help engineers from various industries communicate to manufacturers, product inspectors, and others more effectively. Its widespread adoption could provide a clearer pathway to the application of 3D printing at a larger scale, unlocking the environmental and economic benefits associated with the technology.

“The industry is in a digital transformation right now, moving away from physical 2D drawings, and additive manufacturing is one of the catalysts since it requires digital 3D models,” said Fredric Constantino, an ASME project engineering adviser. “And if you’re working on one of those models, this standard will guide you in making it understandable to both 3D printers and other people.”

With the new guidance, ASME introduces concepts that deal with the nuances of 3D-printing designs, as well as the printing process — including the orientation of a print and whether temporary structural supports are printed.

Tell Us What You Think!