Learn more about the HYTORC Washer and download technical specs here.

The HYTORC Washer offers a simple upgrade that provides improvements in safety, speed, and accuracy. Essentially, this washer works with a double nut cap. The outer cap rests on the serrated outer edge of the washer, while the inner nut cap rotates on the nut.

This principle makes the classic reaction arm (the main cause of personal injury due to crushing) superfluous. The elimination of external moving parts makes this the safest bolting method in the industry.

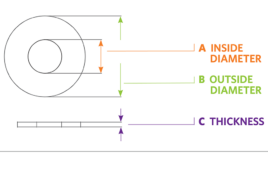

In general, a washer prevents damage to the flange surface and nut, ensures an even pressure and an even bolt force, and prevents leaks. The HYTORC Washer’s serrated edge makes the reaction arm superfluous and prevents entrapment.

Due to the simplicity and effectiveness of this component, the payback time is unprecedentedly short. The washer can also be used vertically and even upside down in combination with both socket keys and ring keys.

By supporting on the bearing ring all round (ie coaxially), shear and bending forces are avoided, which results in a more consistent conversion of moment to bolt force. The HYTORC Washer principle guarantees accuracy and even distribution over the flange bolt force — on average half of scatter. This is the most important condition for a strong, reliable, and leak-free flange connection.

HYTORC

hytorc.com

Tell Us What You Think!