The global industrial fasteners market garnered revenue of about U.S. $80 billion in 2022, according to the latest market data from Research Nester, and it’s showing no signs of slowing down. The same can be said for the adhesives sector.

The global industrial fasteners market garnered revenue of about U.S. $80 billion in 2022, according to the latest market data from Research Nester, and it’s showing no signs of slowing down. The same can be said for the adhesives sector.

There’s been an ongoing surge in construction and industrial markets since the pandemic. This is good news for the workforce and economy, which hopefully continues given recent talks of a recession.

For now, let’s think positively as we review some of the innovations 2022 delivered, including greater automation, training capabilities, and connectivity. The good news is this list merely highlights a fragment of the advances that have come from the fastening industry, which includes adhesives, welding, tools, as well as nuts, bolts, rivets, and screws. We encourage you to browse through Fastener Engineering for more finds.

We look forward to what’s in store for 2023! Happy New Year!

We look forward to what’s in store for 2023! Happy New Year!

1. Resisting vibration

Staytite’s HARDLOCK Nut is designed to resist loosening from vibration longer than most fasteners or locking nuts. It does so via the wedge principle and by using two nuts to play the roles of the hammer and wedge, respectively. A small eccentricity in the sliding part of the convex top of the lower nut acts as the wedge. When the concave upper nut is tightened, the effect is the same as that produced by a hammer driving in a wedge.

Moreover, it’s much more effective to use a screw as this makes it easy to force the wedge into place. Each HARDLOCK Nut passes the American vibration and impact test to the NAS 3350 & NAS 3354 (National Aerospace Standard), and repeated use does not reduce its locking ability.

INF3013 coating provides a targeted and repeatable preload that’s more uniform than typically achieved with black bolt or mechanical galvanize. It also accepts paint.

2. Hydrogen embrittlement protection

Infasco introduced a unique coating system for tension-control (TC) and hex structural bolts, providing several benefits compared to black bolts. According to the company, the new INF3013 far surpasses the performance of mechanically galvanized coatings. In fact, it’s achieved extended corrosion resistance of 1,000 hours of salt spray, which is at least twice that of a mechanically galvanized coating.

Additionally, INF3013 cannot generate hydrogen embrittlement and offers good short-term protection, allowing TC bolts to be inserted into structural connections and tightened at a later date without the presence of corrosive properties (which would typically affect the pre-load).

3. A mobile drilling robot

Introducing Hilti Jaibot, a semi-autonomous, mobile-drilling robot. Jaibot is capable of drilling corrugated metal deck ceilings and concrete walls. It can also identify and map installed profiles of corrugated sheet metal deck structures, align with the digital plans, and automatically adapt planned drill holes to pre-defined installation zones.

To avoid obstacles such as existing installations or structural elements, Jaibot easily detects these objects, adjusting its working area and arm movements accordingly. Users can also benefit from the cloud application, which includes a new 2D structural floor, installation and execution plan uploads, and filtering options (such as by diameter to establish a drilling path).

Hilti Jaibot can drill and mark holes in vertical concrete walls at heights between 0.9 and 4.8 meters. The robot also offers features that improve accuracy and operator safety.

4. Augmented-reality welding

Quality training is essential to ensure proper fastener assemblies, and the same holds true for welded joints — which can be more hazardous and costly.

To ensure safety and minimize material costs, Miller Electric introduced the AugmentedArc Augmented Reality Welding System, a highly realistic multi-process welding simulation solution for classroom training. The system simulates multiple welding processes, blending real-world and computer-generated images into an augmented-reality environment.

Real-time feedback is provided on a student’s technique to help correct errors, reinforcing proper welding practices to accelerate skill advancement before live arc welding in a lab.

5. Sourcing made easy

Early in 2022, Bay Supply launched a unique B2B vertical niche marketplace for fasteners — something that was missing in the industry. The company offers free registration to distributors that sell fastening products within the more than 2,000 identified categories set up on the platform, including several types of rivets, bolts, threaded inserts, and other fastener products and tools.

The AugmentedArc Augmented Reality Welding System introduces students to welding with a simulation system that’s ease to use, affordable, and portable.

One of the platform’s highlights is an RFQ workflow that auto-populates part specifications to streamline the submission process. Buyers can quickly create RFQs and specify the category or brand-specific requirements. The quote requests are automatically syndicated to the relevant suppliers that meet their procurement requirements with a single click.

“Sourcing fasteners requires an incredible amount of time and research online. The current process — multiple websites are sourced, contact us requests, email submissions to multiple vendors, and multiple phone conversations — just doesn’t make sense for anyone in the supply chain anymore,” Clifford Bernard, president and CEO of Bay Supply. “Everyone is chasing the supply, and Bay Supply solves this problem by bringing the supply to the buyers.”

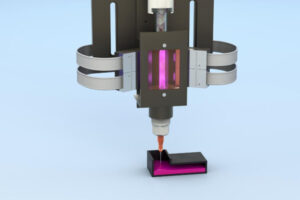

6. One-step adhesive dispensing

DELO developed an innovative process technology, combining adhesive dispensing and pre-activation in a single step. During the process, the adhesive is irradiated during dispensing, which starts the curing reaction before bonding to the component. What’s more, the exposed adhesive areas can be further irradiated and fixed after joining. This provides strength and prevents the adhesive from flowing out and the components from slipping.

Ideal for bonding and encapsulating temperature-sensitive components, the technology offers new options for designing products and processes while reducing costs and CO2 emissions.

The new adhesive technology from DELO is an efficient and environmentally friendly alternative to heat-curing, room-temperature-curing, and dual-curing processes.

7. Intelligent tightening

The GEDORE E-torc Q is an electronic torque wrench that ensures screws are fastened correctly, the first time. This intelligent tool offers intuitive software that evaluates, records, and archives a screw’s connection data. Its measuring and analysis processes cover the torque, torque angle, loosening/tightening, yield point, and further tightening — making it ideal for all tightening situations where maximum precision and reliable documentation are required.

There are currently three models for controlled right/left tightening between 10 and 300 Nm.

The GEDORE E-torc Q: a torque wrench for precise fastener tightening and quality assurance. Learn more in this video.

8. An electromechanical alternative

Clinching (also known as press-joining, is an efficient and reliable joining process that requires no additional components, such as rivets or bolts. Unlike drilling or welding, clinching does not generate heat input and typically requires less energy and maintenance.

To this end, Kistler partnered with BTM to present the first electromechanical joining module optimized for clinching and riveting applications, including assembly processes that require force-displacement monitoring.

This compact NCFC joining module features a high-traversing speed: this new servo press was optimized for clinching and riveting applications

The new NCFC electromechanical joining module ensures complete control and transparency for each production step. The result is improved assembly quality, lower consumption of resources, and reduced CO2 emissions compared to conventional systems.

9. Secure and aesthetically pleasing

Hafren Fastener offers a new range of 2-Hole security fasteners, ideal for the specifier wanting to “class up” an application. The 2-Hole fasteners are tamper-resistant with an appealing aesthetic appearance, which is often specified by architects and designers who desire a smoother, sleeker, contemporary finish.

The fasteners are removable and reusable, making them ideal for applications where security is required while allowing access for routine maintenance. Stocked in A2 Stainless Steel, the range offers excellent corrosion resistance in internal or external applications, so they won’t rust.

10. Extracting damaged or frozen screws

Until recently, there was little innovation for removing corroded, rusted, rounded, or frozen fasteners. GEARWRENCH’s line of extraction tools is changing that.

“We talked with professional mechanics and industrial technicians from all across the country, and they all pointed to massive flaws in their screw extractor tools,” shared GEARWRENCH senior product manager, Jarrett Wolf. “With their help, our Bolt Biter Screw Extractors go above and beyond in addressing those issues to provide a solution that is as effective as it is durable.”

The advanced Bolt Biter Screw Extractors use patented tapered sides, so the tool sits easily and safely into damaged screws while the side and tip-cutting edges provide a reliable extraction. The bi-directional design makes it easy to remove fasteners from the extractor after use and allows fasteners to be retightened as needed.

With 1/4 and 7/16-inch hex-base options, GEARWRENCH’s Bolt Biter Screw Extractors can be used with a ratchet, wrench, or power tool.

Tell Us What You Think!